15 January 2020

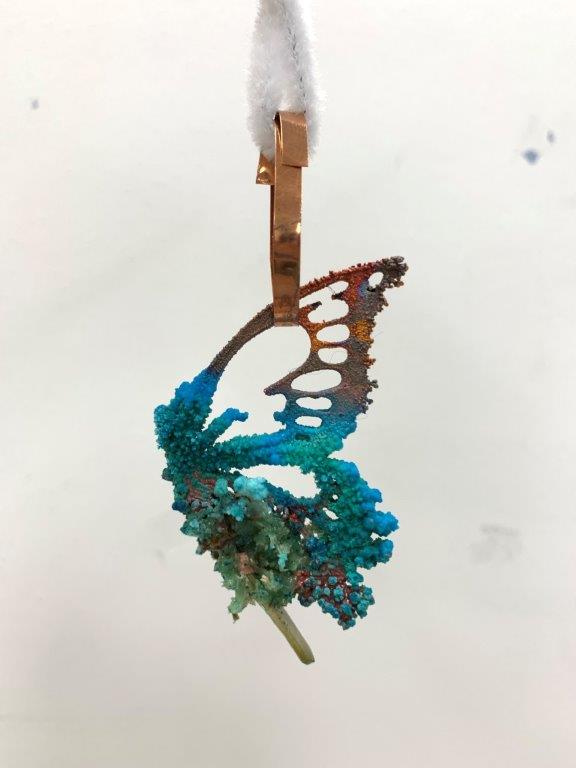

Following the success of the acrylic butterfly, where i coated an electroformed laser cut butterfly object with sawdust, to allow absorptive crystallization and colours from copper corrosion, I decided to flip the materials inside out – using absorbents as base for electroforming and patination, to allow for patination on electroformed surfaces..

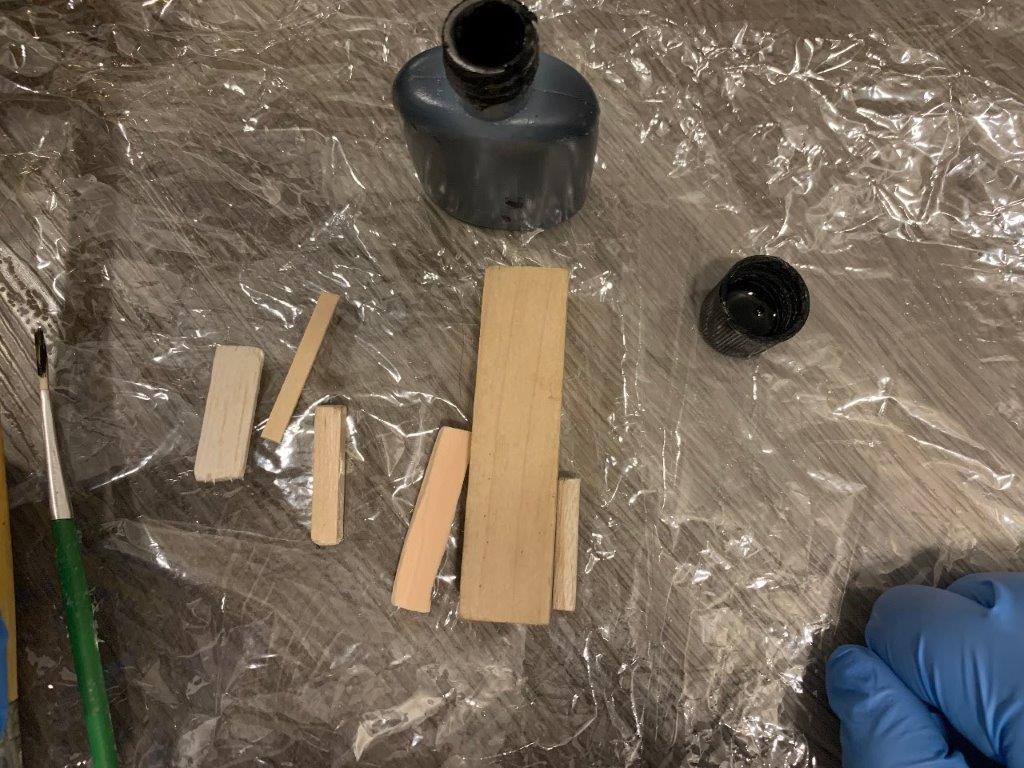

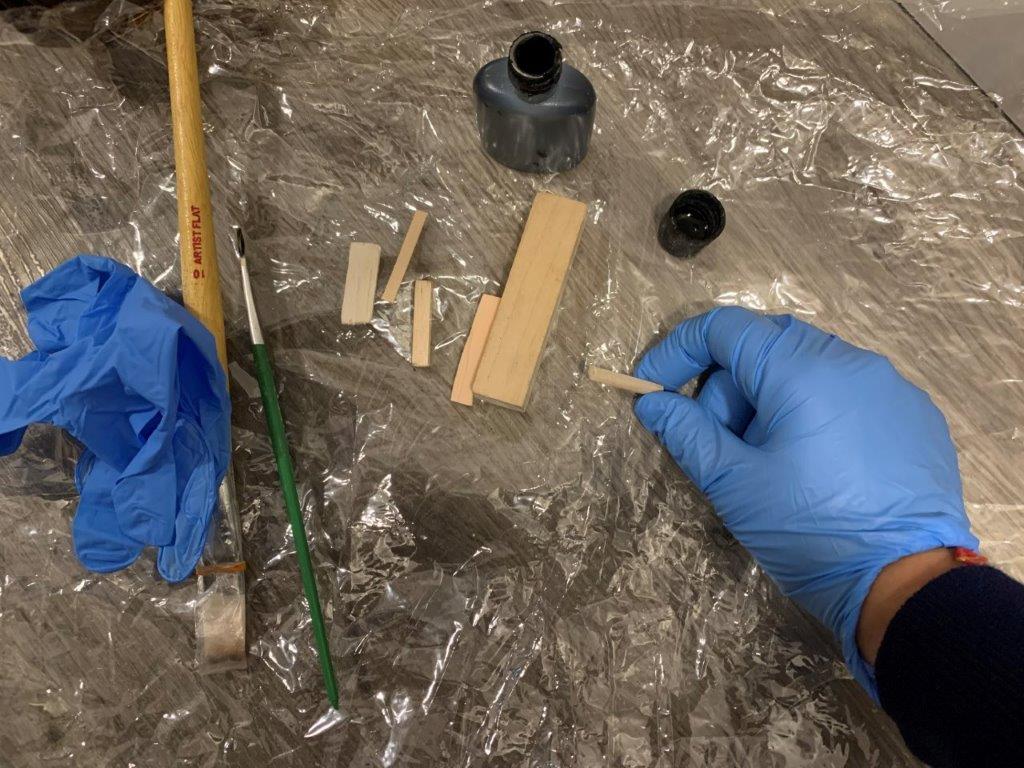

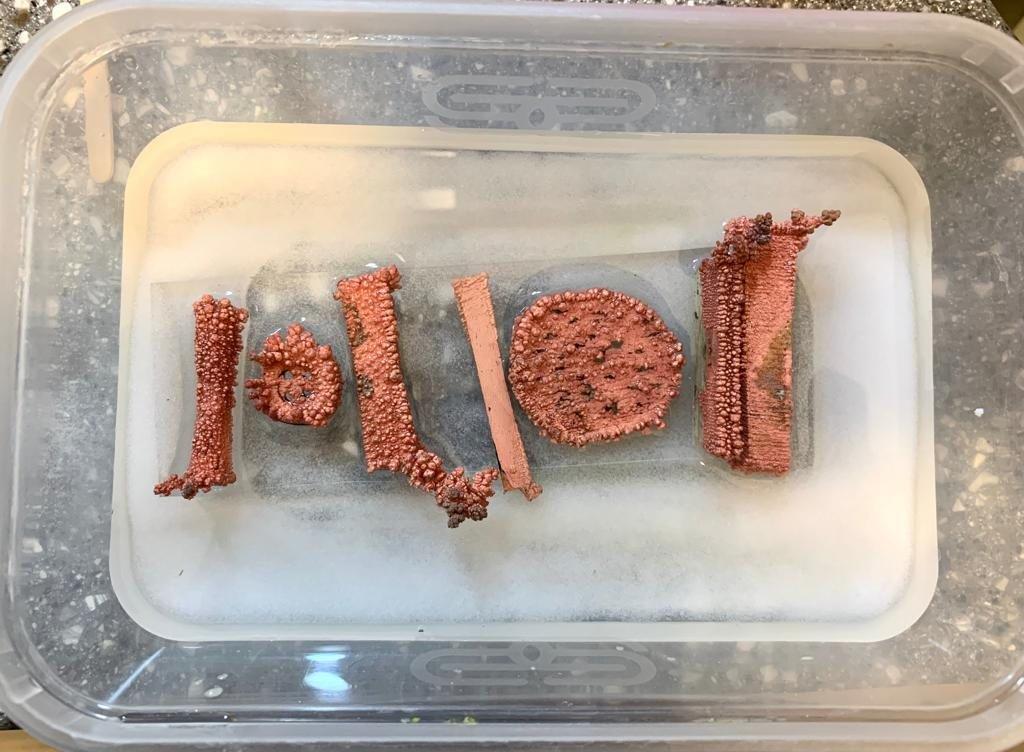

I coated smaller pieces of absorbents such as a balsa sheet, pinewood dowel, high density foam, stirring stick and a wooden button with graphite paint for electroforming.

I left about half the surfaces of these objects exposed, to allow for later absorption of my salt solution..

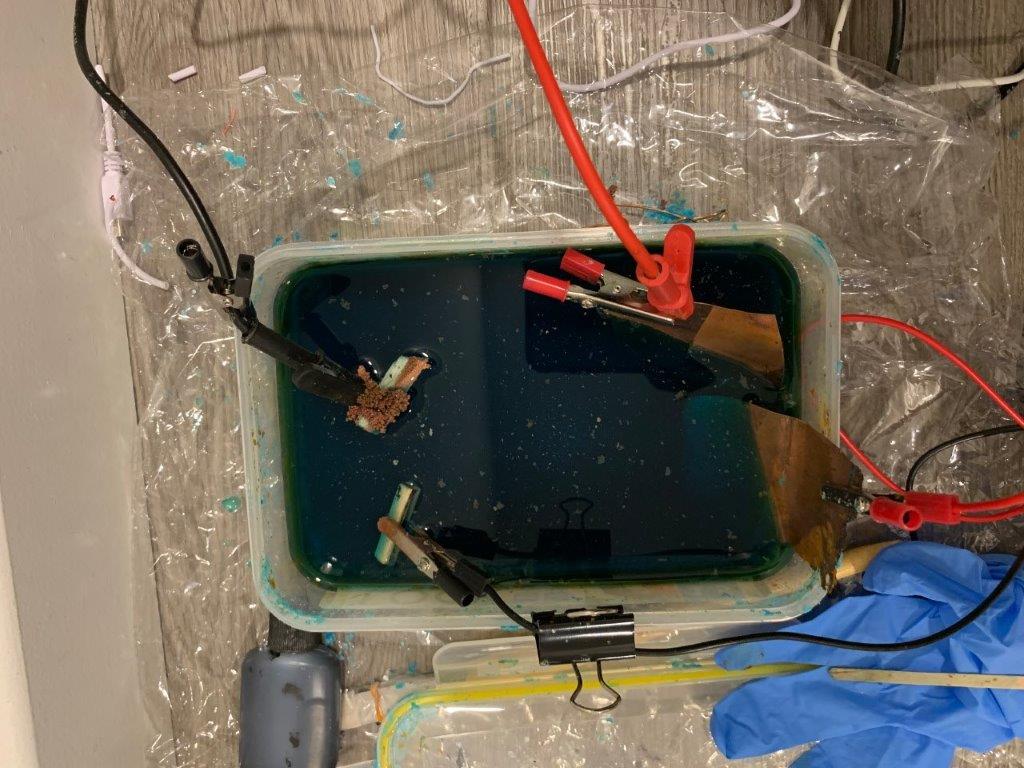

I electroformed the objects for a couple of hours each, such that some, developed dendritic formations from excessive copper deposition, while others, like the flat balsa circle, developed smaller surface nodules of copper.

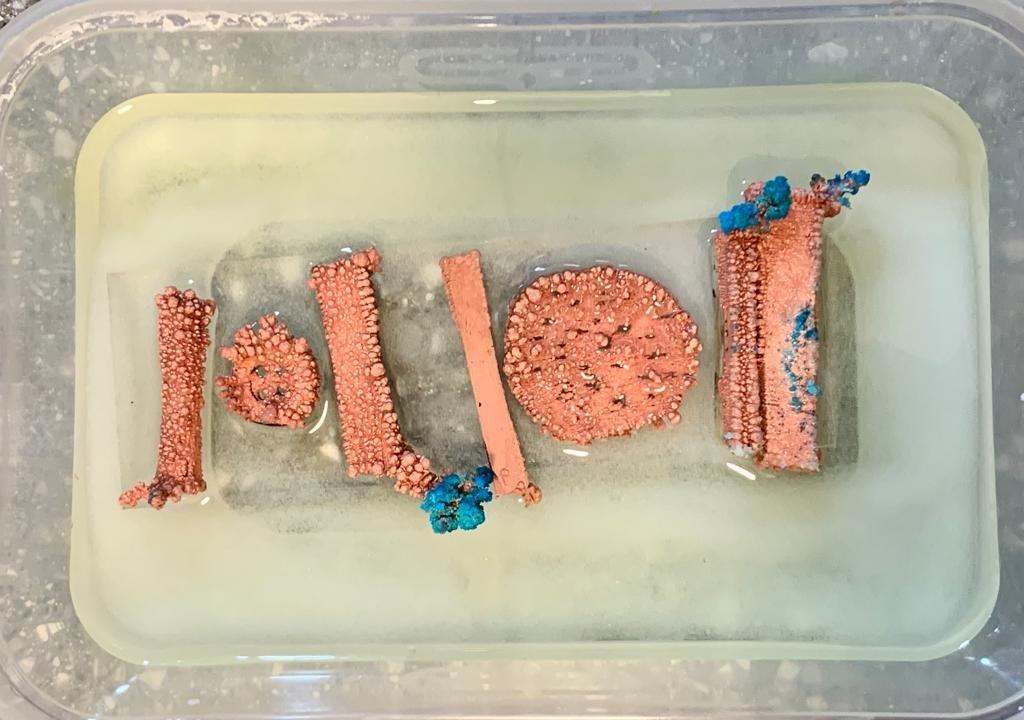

Propping the objects on an acrylic flat base with magnets, I placed the acrylic base within a tub containing my salt crystal solution, such that the exposed surfaces of my electroformed objects were in contact with the solution (for effective solution absorption, yet not submerging the copper coated surfaces fully).

In just a couple of hours, deep blue hues from copper patination started to appear, along with some small salt dendrites from evaporation.