26 November 2019

Electroplating

Impatient to start plating with copper, but without graphite paint to coat my plastic drawings, I started to coat some metal objects through my makeshift electroplating/electroforming setup.

Observations:

- Tin bucket had low adhesion, but Dipped long enough gave a rough rust-like copper coat

- Wire mesh took longer to coat, due to large surface area

- Plastic drawing coated with pencil shavings (solid graphite) and PVA glue instead of graphite paint failed to coat – this might be due to the need for overall conductivity throughout the object, that the shavings did not allow.

- Mechanical pencil lead – immediate uniform coat of copper on account of conductivity and small size

Electroforming

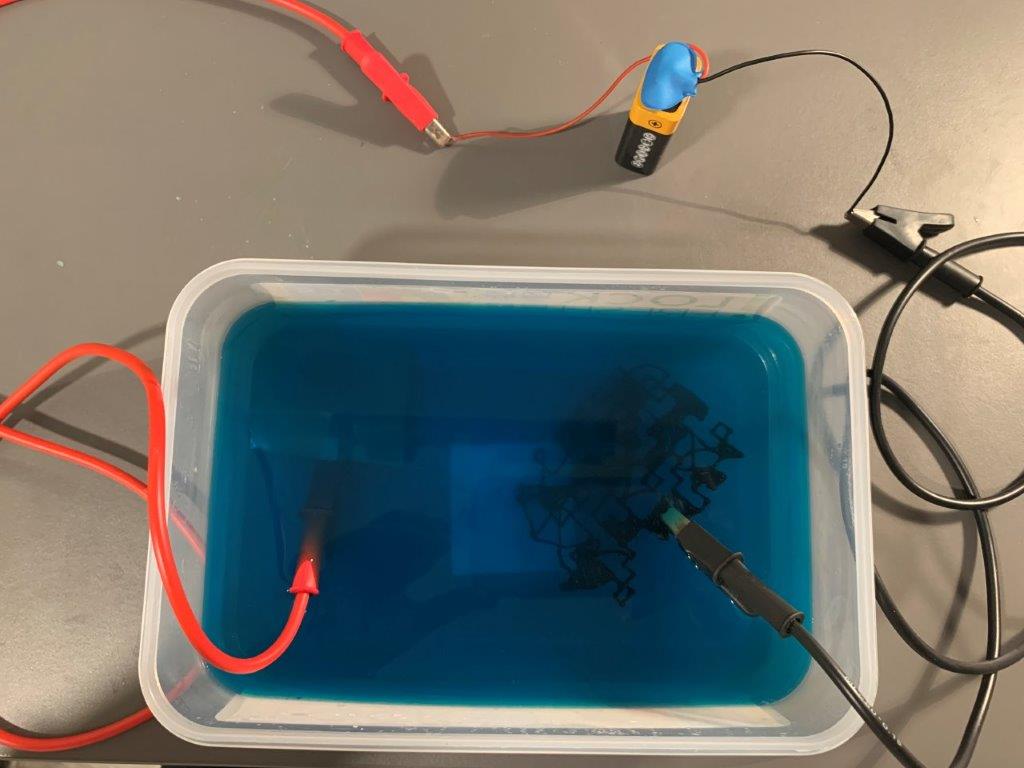

With my Graphite paint finally at hand, I proceeded to paint my plastic drawing and electroform it using the same apparatus.

Painted with graphite for conductivity and adhesion of +ve copper ions

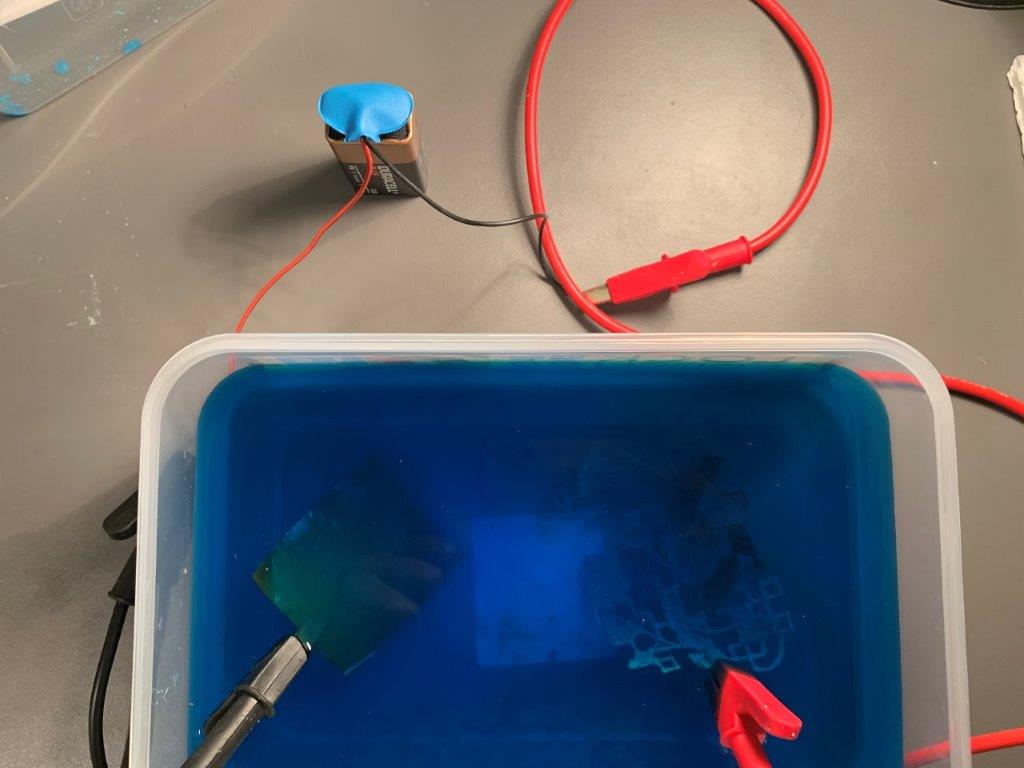

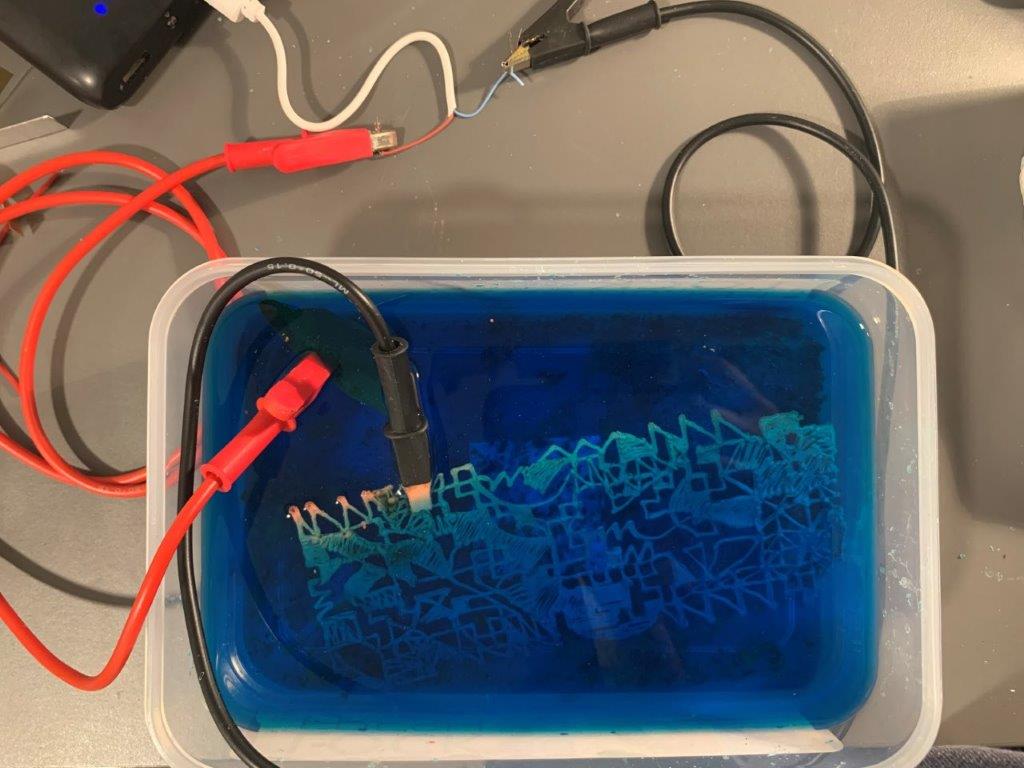

Electroforming apparatus

After 2 hours

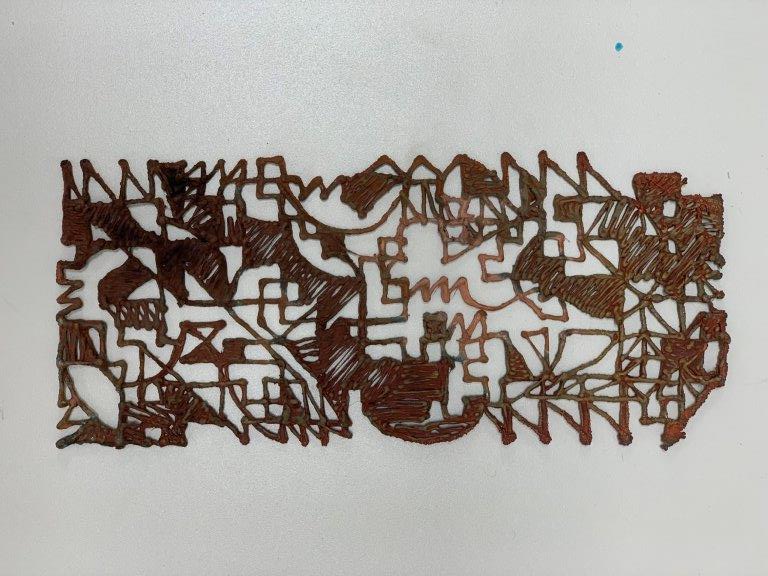

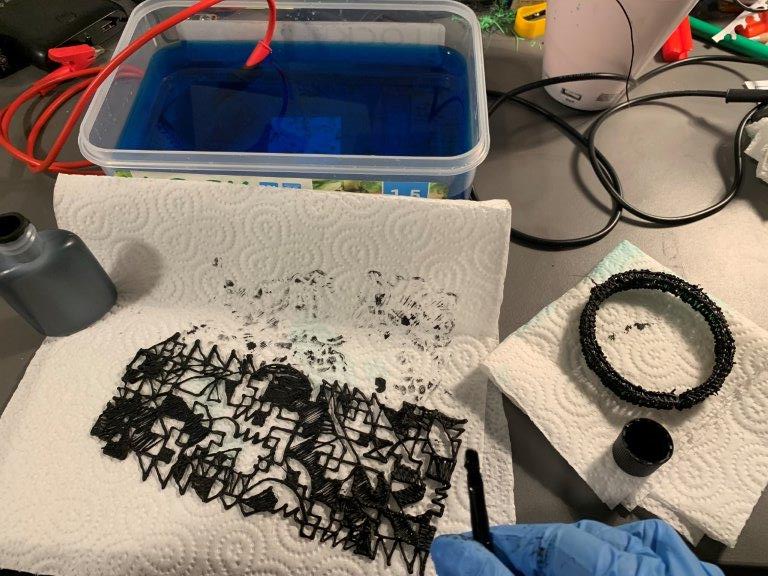

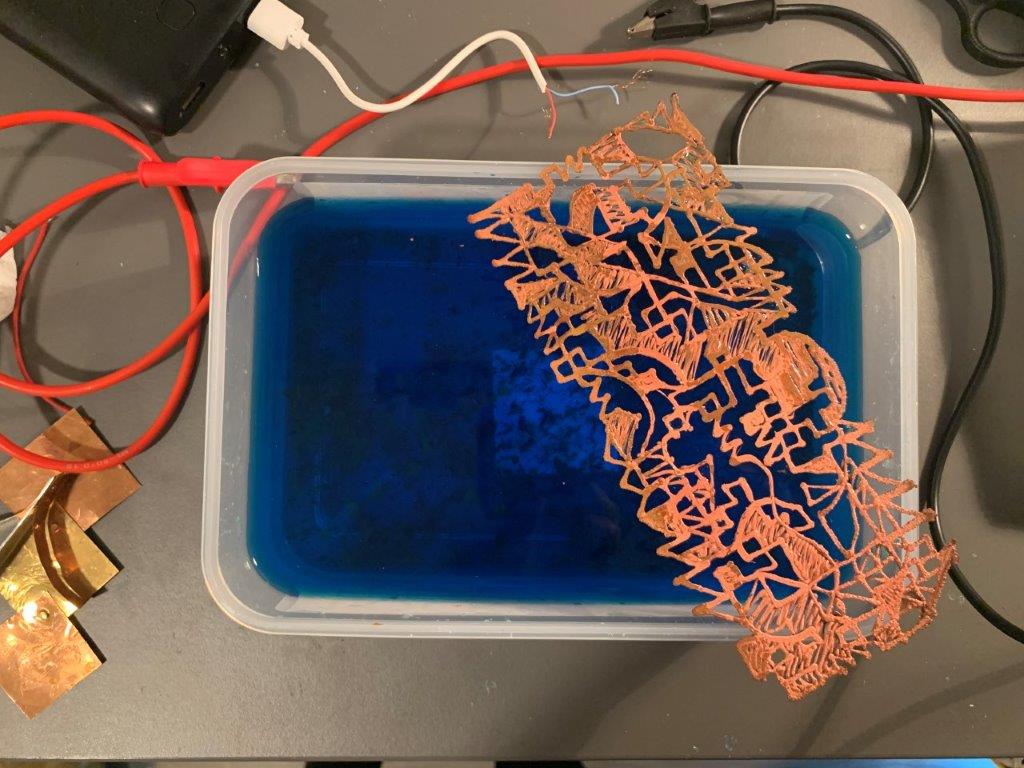

Coated plastic drawing – after 3 hours

After about 3 hours and 2 battery changes, the plastic drawing was almost fully coated with copper. I let it air dry for a bit. Introducing the plastic drawing in the hot copper sulphate solution caused some warpage in the plastic, which I considered using as a shaping method for future flat drawings that i would be coating.

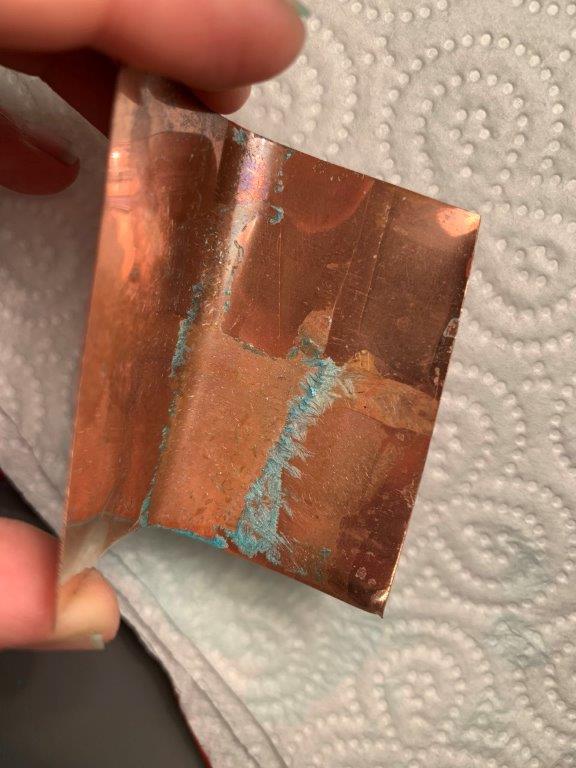

Copper Sulphate Crystals

On a piece of copper I briefly used as anode, I observed needle-like crystals of copper sulphate where the solution hadn’t been cleaned off.

I proceeded to pour some copper sulphate solution onto my copper coated plastic drawing in the hope of growing such needle-crystals at densely coated areas on the drawing. On submerging the drawing into the remaining copper sulphate solution, I noticed copper sulphate crystal deposition on the drawing.

More drawings: electroforming process

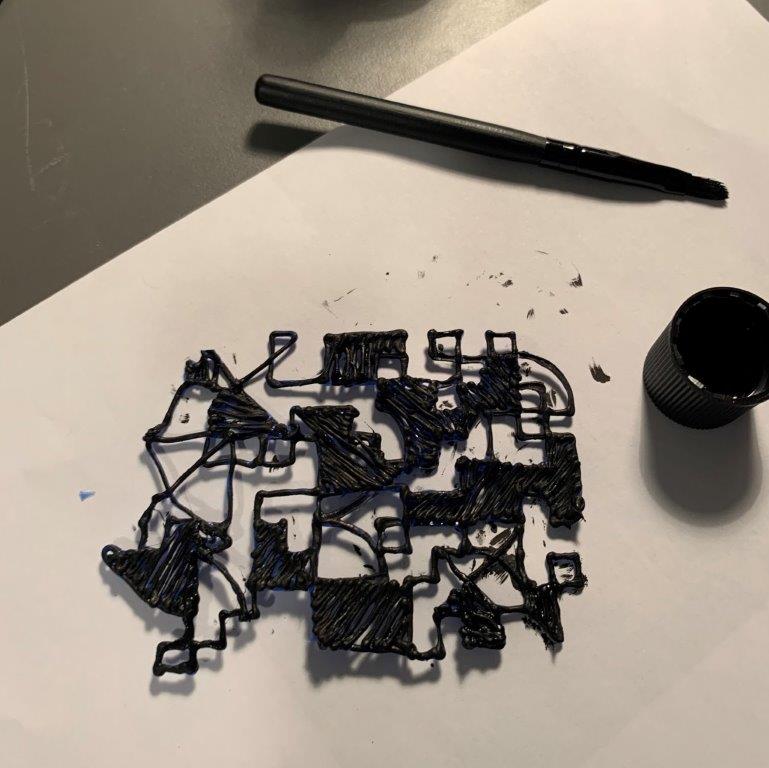

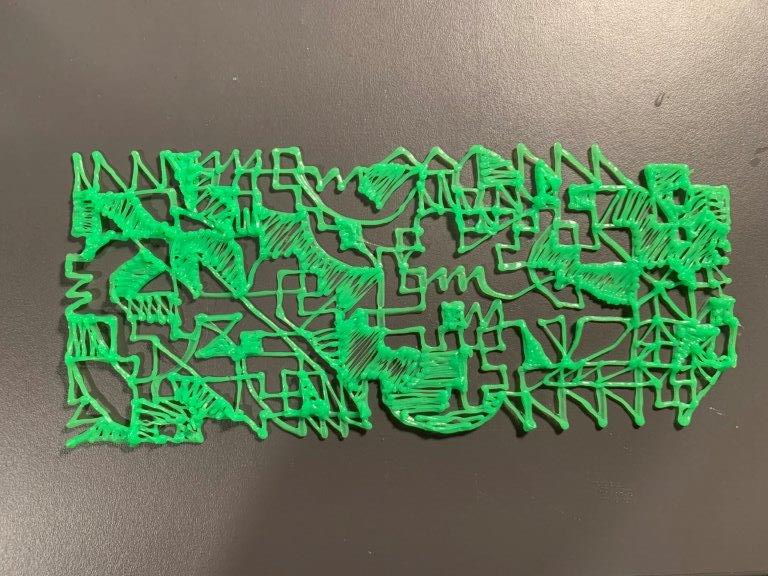

Plastic drawing

Coated with graphite paint for conduction of electric charge

Electroforming in copper sulphate with copper sheet as anode

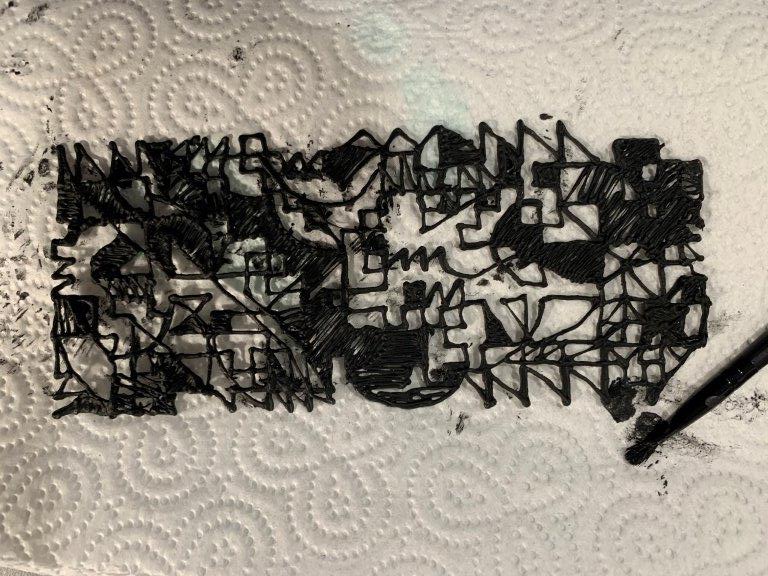

Final copper drawing

Partially electroplated plastic bangle drawing